The new dedicated scroll compressor drives (OJ DC series) allow chillers and AHUs to use more effective motor technologies while providing the means to adjust the compressor capacity continuously.

The new dedicated scroll compressor drives (OJ DC series) allow chillers and AHUs to use more effective motor technologies while providing the means to adjust the compressor capacity continuously.

The OJ Drives allow fans in ventilation and compressors in chillers and AHUs to be operated at different speeds, which results in significant energy savings. A dedicated drive for scroll compressors allows compressors to operate at variable speeds, reducing power consumption in cooling and heating applications compared to fixed-speed motors.

A Drive that Works in Your Application

Perfect for chillers and AHUs, the new series of dedicated drives is key to keeping the compressor’s optimum working condition while securing performance and efficiency.

The OJ DC series has the ability to adjust the speed of the motor to meet the capacity demands. When the need is low, the drive will run at a reduced speed, requiring less energy. The new solution presents a variable speed drive (VSD) that controls the frequency supplied to the motor in the compressor in response to real-time demand on the system.

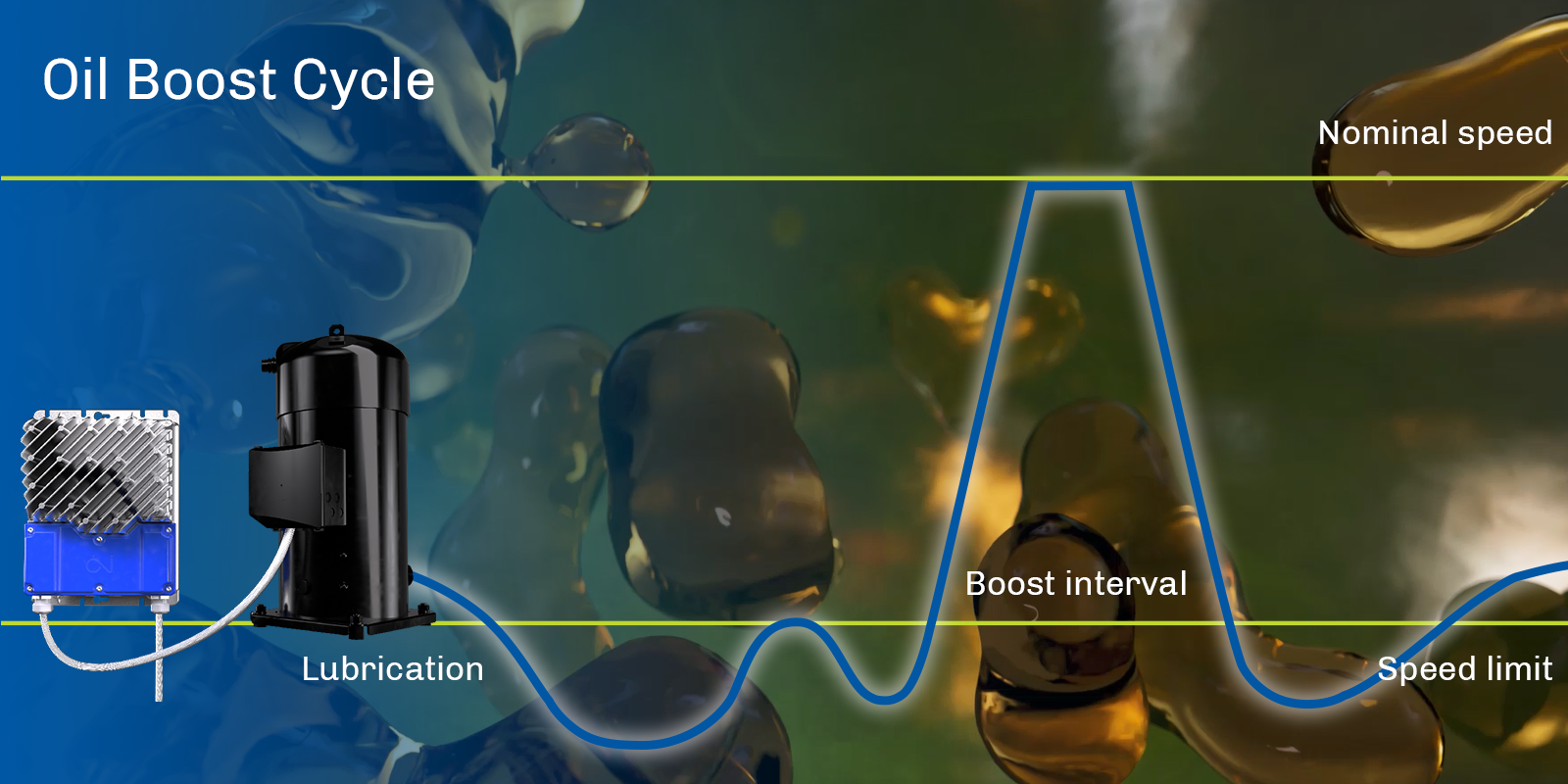

The new drives optimise motor speeds and compressor performance, reducing stress on mechanical and electrical components, prolonging your system’s life and minimising downtime. The OJ DC series warrants optimal performance for permanent magnet brushless motors, especially during start-up and part-load operation. The oil handling function ensures compressor lubrication with precise oil management.

The dedicated drives for compressor systems comprise five power variants (from 4 to 15kW). The new DC series is built on proven OJ technology used in the existing DV series. Both DV and DC series result from combining EC (electronic commutation) and FC (frequency converter) technologies.

The dedicated scroll compressor drives carry considerable advantages for applications where efficiency, durability, and reliability are essential: significantly lower energy consumption and operation costs.

Perfect for Decentralised Solutions

Choosing between a central or decentralised solution depends on the building’s purpose and cooling and heating requirements. Still, decentralised systems are gaining popularity among building owners and facility managers, as they are cheaper, easier, and faster to install. They can better meet the demands of different tenants in different parts of the building throughout the day and night and produce much less noise. At the same time, buildings with overly large central AHU systems and large single-compressor chillers typically perform poorly during off-hours and part-load conditions.

The new OJ DC series fits perfectly in decentralised systems as they perform better under varied conditions. The dedicated scroll compressor drives work perfectly in a modular and flexible solution offering more possibilities when configuring the system. The DC series reduces cable length, especially the expensive ones.

Durability has been an essential keyword throughout the R&D phases, rendering DC ideal for central and decentralised locations where environments get rough. The OJ DC series has been tested for continuous and unaffected performance. It continuously works in almost any setting from -40°C to +50°C / -40°F to +122°F and has high scores from the IP and NEMA protection class, respectively, IP54/IP65 and NEMA 4X. These ratings are more than sufficient in most situations.

Energy-Efficiency

By adjusting compressor speed to match the cooling load of the building, the DC series ensures higher efficiency and comfort levels.

The OJ DC series enables that the motor only delivers enough energy to power the compressor and no more, eliminating energy waste. The OJ DC secures efficiency of up to 97%. Analyses have shown that a 20% reduction in motor speed can lead to a 20% energy saving (source: GAMBICA).

A dedicated drive for scroll compressors in your chiller or AHU system is more efficient, uses less energy, and assures optimal lubrication control and flawless performance regardless of variable loads or capacity.

Easy Set Up & Monitoring

The OJ DC series has pre-configurable settings that help maximise productivity. The removable front cover facilitates easy access to connectors for instant system configuration. The drive unit can be mounted with the scroll compressor at the factory to be tested before installation.

OJ compressor drives offer a large user-friendly connection area, holding both Modbus RTU and BACnet MS/TP protocols and a 0-10 V communication control. BACnet ensures that information is standardised and exchanged between a building’s sensors, actuators, and controls. Equipped with BACnet MS/TP, the OJ DC can now be part of the building automation. BACnet MS/TP is running on RS-485.

“The dedicated scroll compressor drives carry considerable advantages for applications where efficiency, durability, and reliability are essential: significantly lower energy consumption and operation costs.”

Lasse Larsen, Product Manager Compressor Drives at OJ Electronics

About the OJ Drives® for Compressors

About the OJ Drives® for Compressors

- 5 power variants

- 2 enclosure sizes

- PM and BLDC motors

- Operation from -40°C to +50°C

- BACnet MS/TP

- UL 61800-5-1, CS22.2.174 recognized

As the OJ DC series comes with a fully integrated EMC filter, it meets emissions and immunity norms in industrial and residential areas EN 61800-3 (C1 and C2). The OJ DC product series is cULus recognised according to UL 61800-5-1 and CS22.2.174.

Click here for details on the OJ DC’s new dedicated drives for compressors.