It is with pride at the success of the project that the production manager can look back at the last five years since the establishment of a new type of department – a QRM cell intended to assist the development and testing of prototypes. Today, the QMR cell is a success story with clear, measurable benefits.

“The lead time for prototypes has been reduced by more 50%. We have reached our goal of being able to produce a prototype in three days – and we often manage to do it in less than two days. Previously, we allocated two to four weeks for this,” says Lone Gloy, production manager at OJ Electronics.

QRM (Quick Response Manufacturing) is a strategy that allows you to reduce lead times throughout your organisation. According to the man behind the concept, professor Rajan Suri, it can bring your products to market faster and with greater reliability. In 2014 and 2015, this was precisely what OJ Electronics needed. The company embarked on a new growth strategy, with a long list of new products on the drawing board. prototype production took too long and interfered with the ongoing production. Lone continues:

“We thought ourselves to be too slow in launching our products on the market. Our goal was therefore to improve our ability to introduce new products. We wanted a faster delivery time and fewer operational disruptions. Just by chance, we came across a new way of doing things, and I wanted to try it out.”

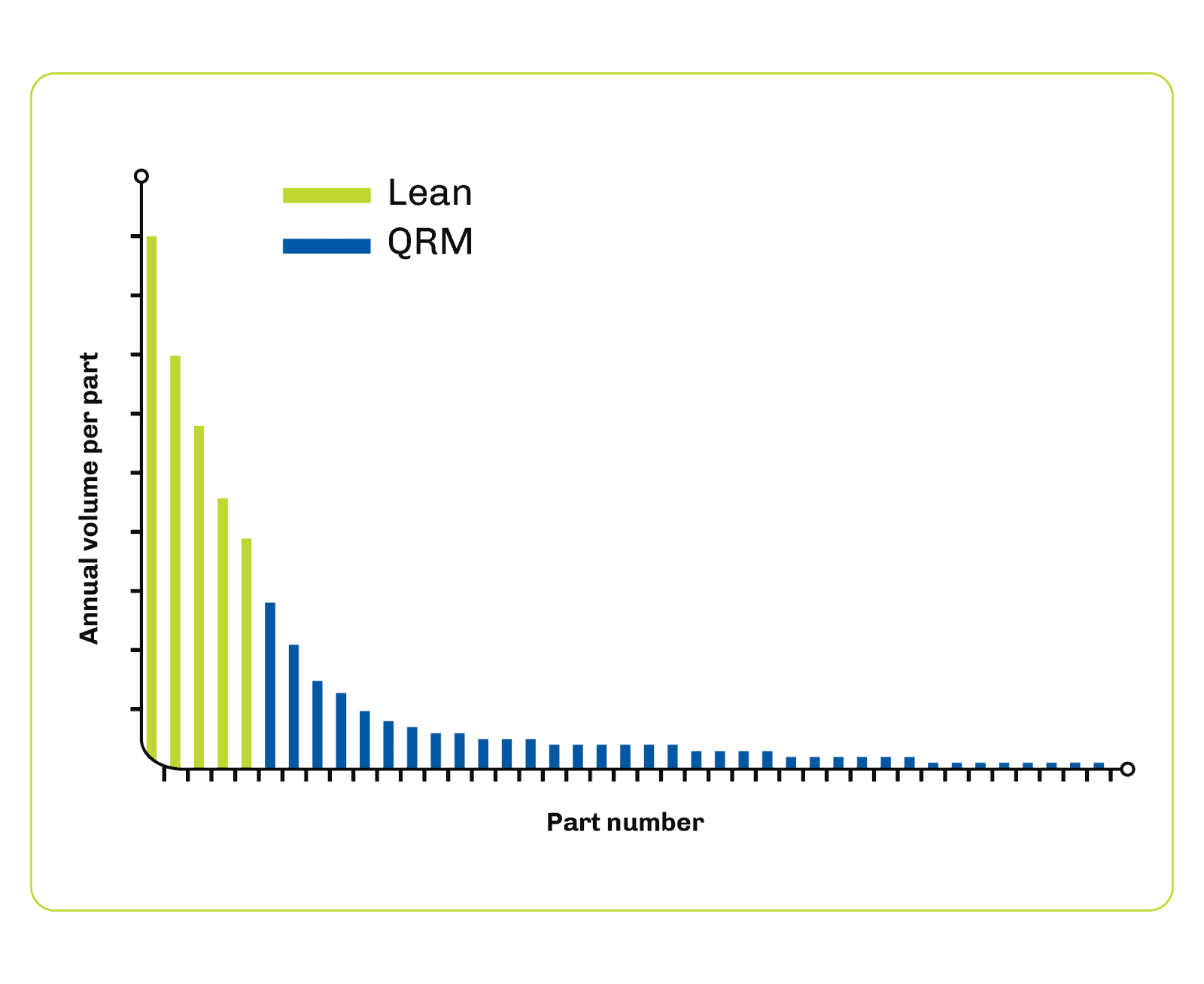

Lone heads the QRM cell, which from its start was staffed with three employees. In order to find the most motivated employees, OJ decided to post the positions internally rather than appoint anyone. The three employees were trained to work cross-functionally and to be skilled in different types of tasks. These include modifications within development, production, tests, administrative tasks, planning, etc. When there are no prototypes to build, the cell provides assistance with tasks for products in the high mix/low volume category.

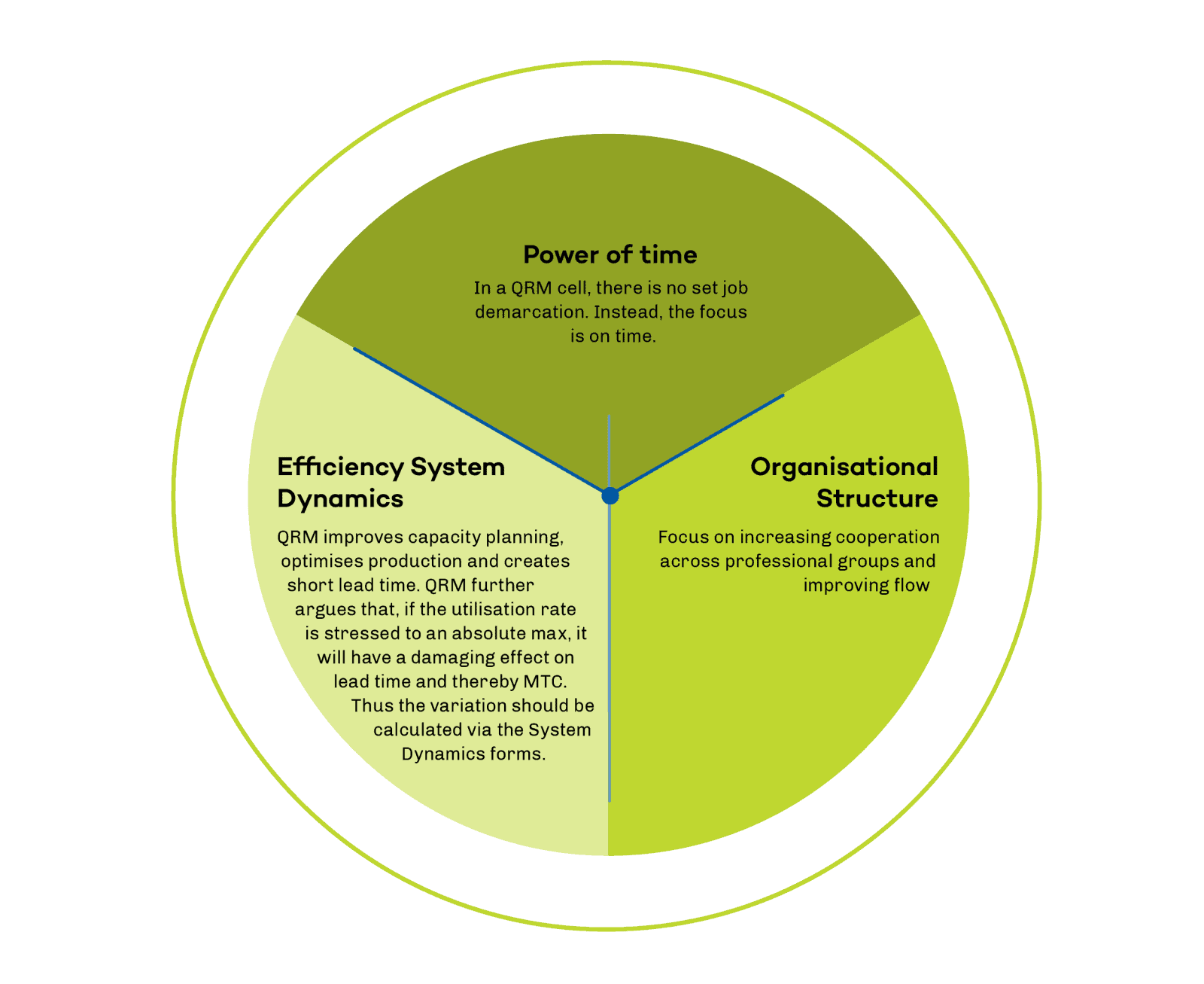

“It is a departure from the traditional way of thinking about production in Denmark. In a QRM cell, there is no set job demarcation. Instead, the focus is on time. The more the cell can do by itself, the faster the product can be launched. This is some of the most exciting work I have been involved with,” explains Lone.

OJ Electronics has the courage and will to step outside its comfort zone. Here, new exciting adventures await, but they are not without challenges. Challenges the company is more than willing to accept.

“The first 12-18 months, we faced obstacles. This was a new way of thinking, and the cell solved issues combining forces and collaborations differently. It was therefore very important to maintain faith in the project throughout, so that we could establish and initiate it. Fortunately, it started having an effect quite quickly.”

Lone emphasises the persistent driving force stemming from the collaboration with her manager, Allan Ohlsen, as well as sparring with the consultancy company QRM Danmark. Without this, the QRM idea would not have survived all the bumps in the road. Its huge success she attributes with special thanks to the proficient employees and colleagues who worked hard to achieve the positive results:

“It has been a huge success, and it’s important to believe and hold your ground, until you can reap the rewards. After all, we do mess with EVERYTHING that would ‘normally’ be done outside production. However, OJ has a culture where we like to think out of the box, and that’s cool. Management provides support and trust, so that we can try new things.”

This way of thinking – i.e., a focus on increasing cooperation across professional groups and improving flow efficiency – has also influenced other parts of OJ Electronics. In 2017, QROC was established. This is an administrative cell that was tasked with optimising the process of ECOs (Engineer Change Orders). The team handles existing products that has to be changed, updated or redesigned. Before this, these tasks fell to many different departments. Today, the QROC team coordinates from start to finish, which has resulted in a 75% reduction in the number of ongoing tasks – a drop from 80 to 20. Furthermore, the waiting time has been reduced, and the number of do-overs (products not living up to OJs’ high quality standards and as a result needed further attention) are nearly zero.

“At OJ, the QRM concept is here to stay. The results are just too good,” concludes the production manager.

The very tangible success of the QRM concept at OJ Electronics has also attracted a lot of attention from outside the company. In Denmark, the company is among the leaders within this concept, which is right now – as the value is becoming obvious – gaining grounds domestically. This has resulted in a lot of guests from countries such as France, Belgium and the Netherlands. These guests want to see the QRM cell in action and to hear about the company’s experience.

If this has also stirred your curiosity to learn more about how we implemented a QRM and QROC unit at OJ Electronics, you are welcome to contact our production manager, Lone Gloy, at log@ojelectronics.com.

Facts on QRM

QRM – Quick Response Manufacturing

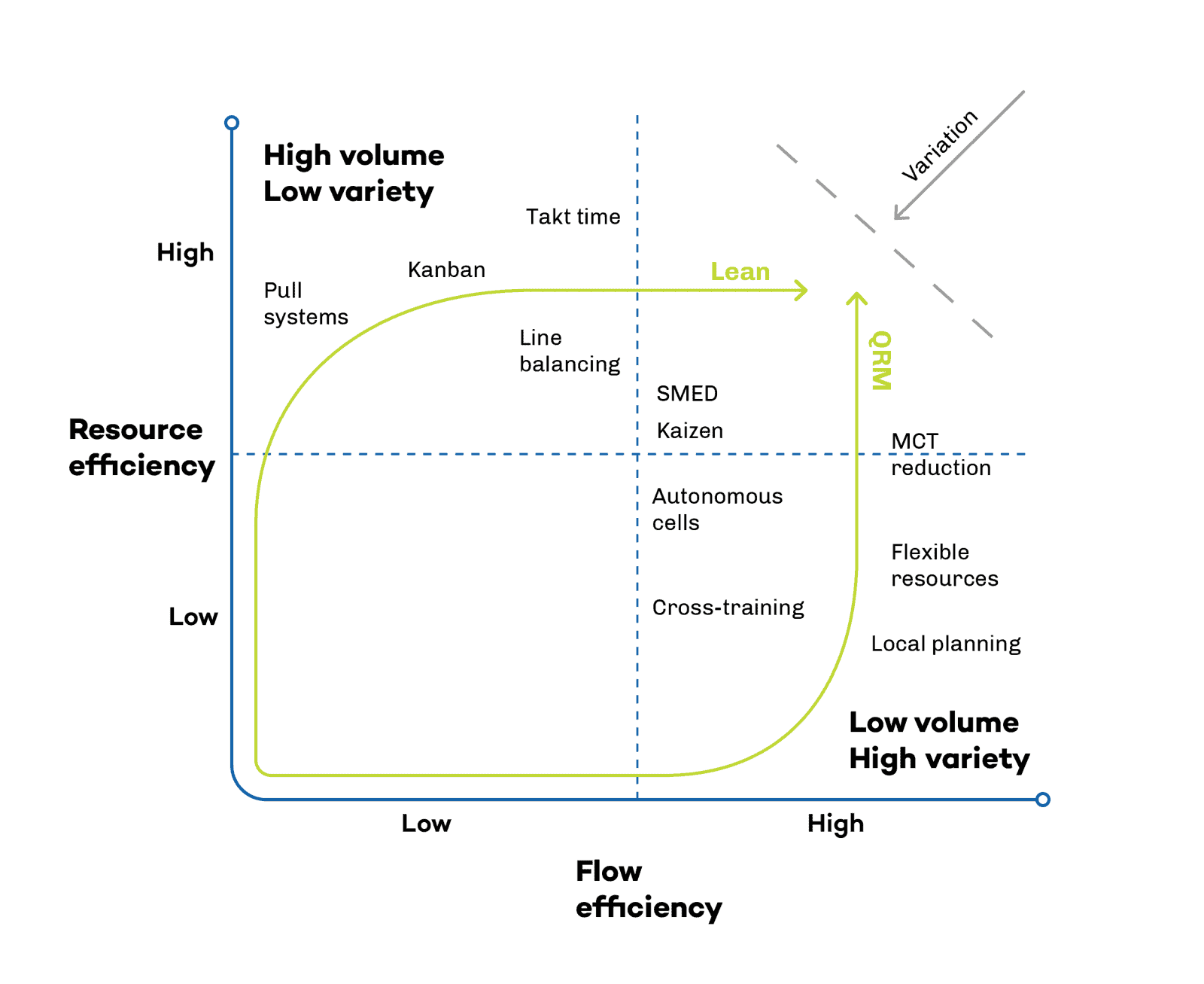

- A strategy with focus on the ability to react and adjust quickly in an environment with great and many variations

- Based on the approach of viewing your organisation as multiple smaller units – not departments, but multi-functional team, each capable of swift adjustments. The tasks are organized in order to move from silos t teams with focus on flow. The main thesis being reduction of lead-time though elimination of time spent on all processes.

- The concept has been developed by Professor Rajan Suri from the University of Wisconsinn-Madison and in collaboration with more than 200 American organisations. Furthermore, Rajan Suri has published 2 books and numerous articles in several journals on the QRM-concept

Source – Translated from: QRM Danmark, qrminstituttet.dk og rajansuri.com

QRM – Quick Response Manufacturing

– A concept developed by Professor Rajan Suri, University of Wisconsin-Madison, in collaboration with more than 200 American companies. Rajan Suri has published 2 books and several articles on the subject of QRM.