Devoting years to tackling power line noise

Power line noise is a growing issue – partly due to changing consumer behaviour, and partly due to a lack of regulation in the 2 kHz to 150 kHz range. Responding to the latter, OJ Electronics has spent years developing a state-of-the-art GFCI module with vastly superior immunity to power line noise.

Power line noise linked to lack of regulation

OJ Electronics has devoted thousands of man-hours of specialist work to creating an updated GFCI module for its thermostats, ensuring state-of-the-art immunity to power line noise.

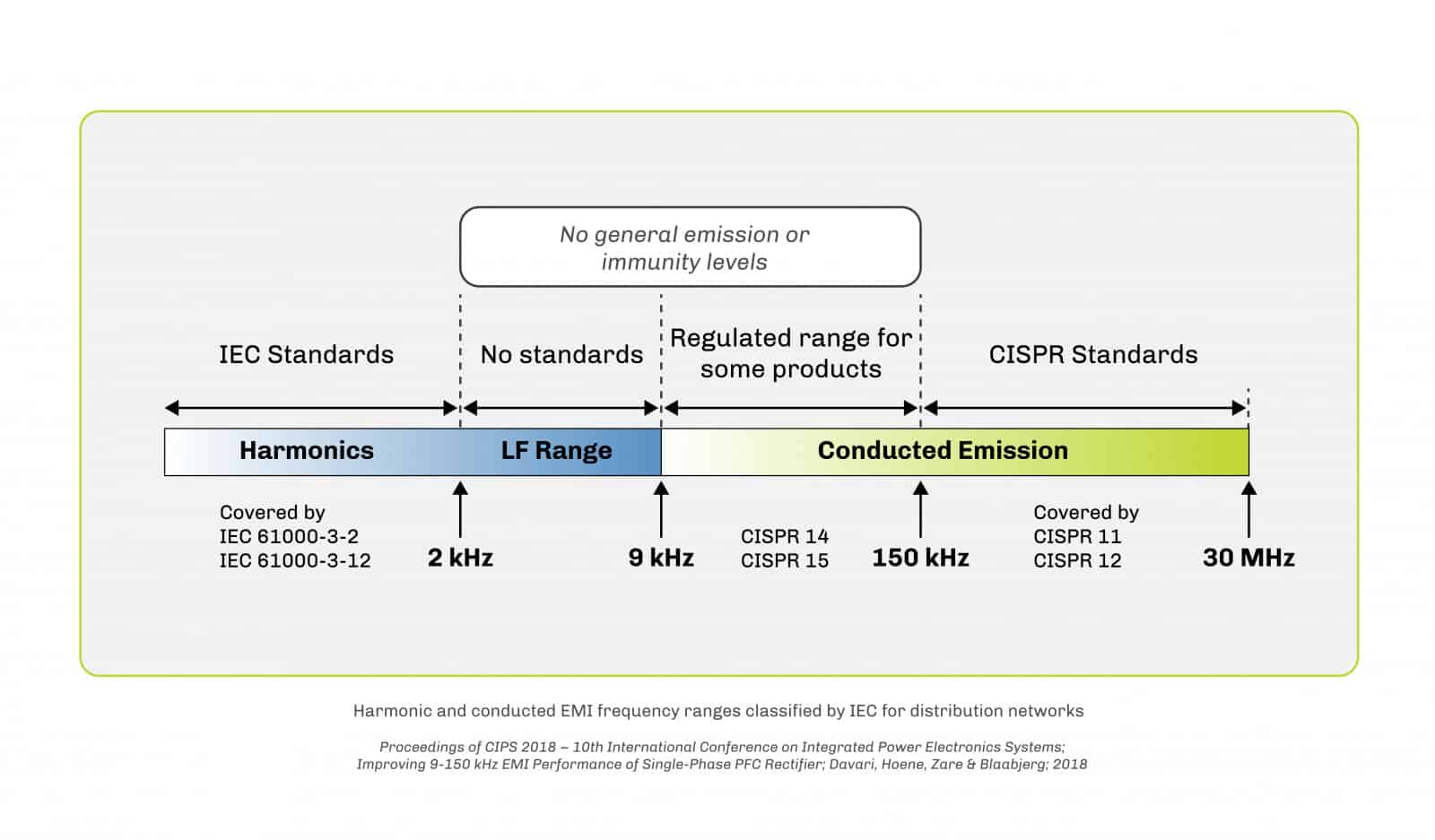

”Several years ago, we grew concerned that noise issues were a growing problem in the USA and Canada – an increasing number of products were causing power line noise, with common culprits in households being microwave ovens, LED lighting, heat pumps, induction stoves and home EV charging stations. Prodding deeper into the issue, we found that part of the problem was that while power line noise is regulated by international standards in the 0-2 kHz range, the span from 2 kHz to 150 kHz currently remains unregulated for many product groups. At same time, we expect the future to bring even more potential noise sources with growing numbers of EV chargers etc., so there was a definite need to do something. And while work on regulating this issue is underway, the process is inevitably long, so we decided to take action ourselves: we set out to increase noise immunity in the parts we can control, which specifically meant the GFCI modules in our thermostats for underfloor heating,” explains Anders Hogh-Skov, product manager with OJ Electronics.

He goes on to add that: “Obviously, even when the new legislation is in place, it won’t be retroactive, so all the problematic products currently installed and on the market will continue to be a potential challenge for years to come. All the more reason to act now.”

Focusing attention to the standardisation gap

Accordingly, the main focus while developing the new GFCI module was to increase noise immunity in the frequency range from 2 kHz to 150 kHz. ”Of course, this didn’t mean that we ignored the areas outside this range; for example, we tested the 150 kHz to 230 MHz range with a safety factor of ten times up against UL 943. But we had to set up our own, strict test requirements below the 150 kHz line, which we defined on the basis of field tests, investigations and theoretical studies. The work involved a lot of digging to establish a firm data basis, seeing exactly where we should focus our efforts”.

Tested in real life

Real-life tests were also part of the process: ”We’ve worked closely with other experts in this field,” says Anders, ”to make sure that the effect would be felt in practice. For example, long cables can exacerbate noise-related issues, so we tested our updated thermostats thoroughly with long cables from market leaders”.

Vastly improved immunity

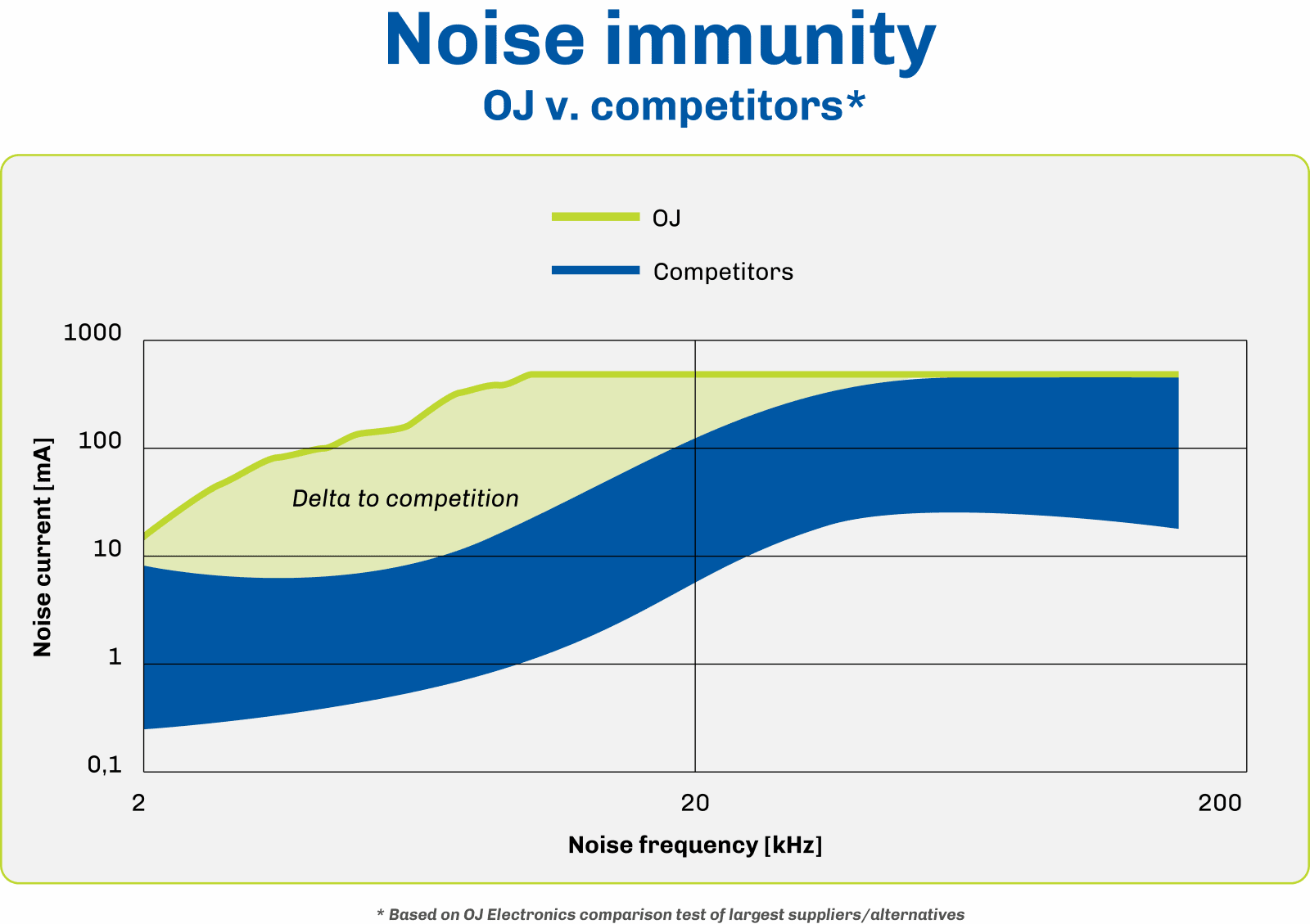

The results speak for themselves: ”In some ranges, we saw that immunity to nuisance tripping was improved no less than 100 times! In the lowest-ranking ranges, we still see improvements of up to ten times. So these GFCI modules are very well protected against noise – and ready for a future where power line noise are expected to grow.”

Added safety features, too

The development work brought along other benefits as well: ”While we were solving the matter of immunity to power line noise, we also took the opportunity to make certain adjustments to all the parts where we saw potential for even better functionality and safety. Examples include improved GFCI self-check at power on, new relays, and improved welded contact detection at power-up and in monthly tests. Basically, all these additional improvements are about added safety, including features that go beyond UL standard requirements. While improved immunity to power line noise is the main feat, these new traits are added extras to what we confidently call state-of-the-art GFCI.”

The new GFCI module is being implemented in production now in all relevant products. The changes involve no visual or functional changes for end-users or installers – they will simply benefit from superior immunity to power line noise and new safety features.

The new GFCI module benefits in brief

- Superior noise immunity – up to 100 times improvement in immunity based on OJ Electronics’ own very strict requirements and compliant with UL 943 requirements effective 2021-05-05

- All tests conducted by both OJ Electronics and UL

- Added safety features, such as extended automatic monitoring, improved self-check and welded contact detection