In the past couple of years, Lucam and VFA Solutions have partnered with TNO (Netherlands Organisation for Applied Scientific Research). This independent research organization connects people and knowledge, aiming to create innovations that boost the sustainable competitive strength of industry and society’s well-being. TNO believes in the joint creation of economic and social value, focusing on transitions or changes in nine social themes; among their pillars is “Energy: Faster towards a sustainable energy supply.” With SchoolVent, TNO developed and tested a ventilation system with 80% lower cooling and filtration energy costs for schools and daycare centers. The project was carried out with the Top Sector Energy Subsidy from the Ministry of Economic Affairs in the Netherlands.

In the past couple of years, Lucam and VFA Solutions have partnered with TNO (Netherlands Organisation for Applied Scientific Research). This independent research organization connects people and knowledge, aiming to create innovations that boost the sustainable competitive strength of industry and society’s well-being. TNO believes in the joint creation of economic and social value, focusing on transitions or changes in nine social themes; among their pillars is “Energy: Faster towards a sustainable energy supply.” With SchoolVent, TNO developed and tested a ventilation system with 80% lower cooling and filtration energy costs for schools and daycare centers. The project was carried out with the Top Sector Energy Subsidy from the Ministry of Economic Affairs in the Netherlands.

Together, they co-developed the SchoolVent project with a local school facing issues with air quality and energy efficiency in their buildings. This article will discuss the challenges faced by the school, the solutions implemented by Lucam and its partners, and the results achieved. Furthermore, we introduce Lucam’s new project model for schools, based on their success in this renovation project, to which we are proud to have contributed.

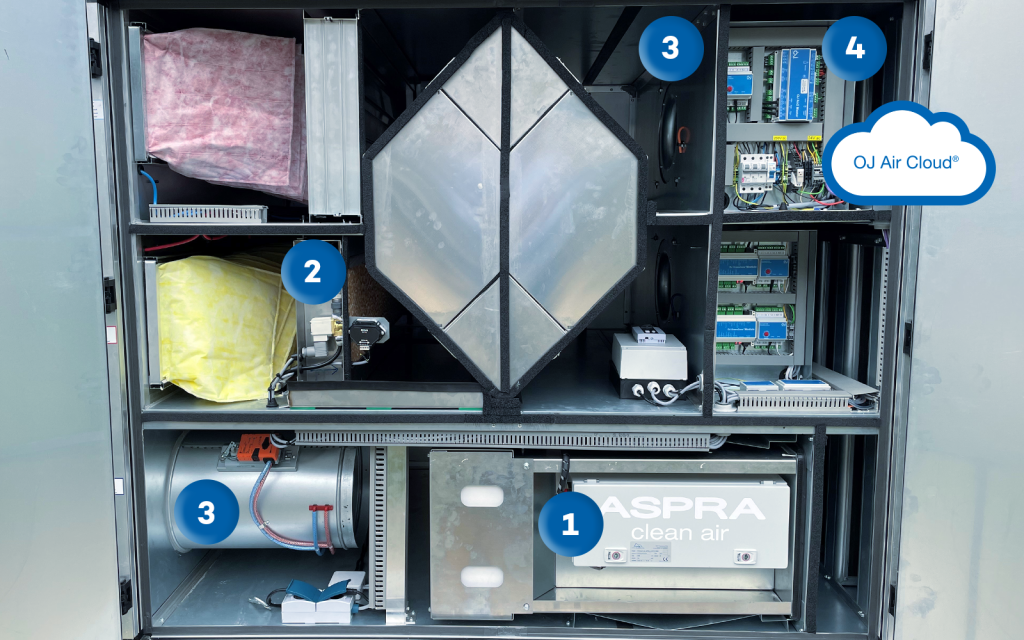

Lucam is a developer and manufacturer of air treatment systems and applications. They have elaborated the SchoolVent concept and, thanks to OJ Electronics, could develop efficient monitoring for reporting performance and results. Lucam’s experience in managing several components of the ventilation system was decisive in the success of the results.

Lucam is a developer and manufacturer of air treatment systems and applications. They have elaborated the SchoolVent concept and, thanks to OJ Electronics, could develop efficient monitoring for reporting performance and results. Lucam’s experience in managing several components of the ventilation system was decisive in the success of the results.

VFA Solutions develops and manufactures technologies, products, and solutions for air purification and filtration. Their expertise in technology development, aerosols sensor technology, and measurements was vital to the project’s success. VFA created a tailor-made version of their own ASPRA electrostatic purification and filtration systems for the integration inside the AHU for high filtration efficiency yet with an extremely low-pressure drop (resistance to airflow).

VFA Solutions develops and manufactures technologies, products, and solutions for air purification and filtration. Their expertise in technology development, aerosols sensor technology, and measurements was vital to the project’s success. VFA created a tailor-made version of their own ASPRA electrostatic purification and filtration systems for the integration inside the AHU for high filtration efficiency yet with an extremely low-pressure drop (resistance to airflow).

The Rise of an Innovative Project for Ventilation Systems in the Netherlands

It all started with a pilot project in a school in Zeist, Netherlands, after mediation by the Province of Utrecht. The school was facing several issues related to air quality in its buildings as they are near busy roads. They had no ventilation system, relying only on window airing, which resulted in poor indoor air quality and high temperatures in summer and low during winter. This affected the students’ and staff’s health and comfort. A traditional ventilation setup could increase the school’s operating costs, so they needed an efficient system for indoor climate and energy-efficient.

The pilot project for this totally new ventilation system started with five classrooms in the Jordan Montessori Lyceum Utrecht school. The solution should improve indoor air quality, reduce noise from the highway through the open windows, and lower operating costs. To address these issues, TNO proposed and implemented several individual solutions tailored to the school’s specific needs. They comprise different areas and partners distributed in four key areas:

Air filtration – implementing filtering technology to permanently remove fine dust, particles, and pollutants from the air with a low-pressure filter.

Air filtration – implementing filtering technology to permanently remove fine dust, particles, and pollutants from the air with a low-pressure filter.- Cooling – a classroom with children is a heat source, requiring cooling during warm periods. An indirect adiabatic cooling (dew point cooling system) reduces energy consumption by using outdoor air to cool the indoor air.

- Ventilation – guaranteeing sufficient ventilation with fresh outside air is vital for a healthy and pleasant learning environment.

- Monitoring – implementing an adjustable control system for proper functioning within class A that can provide periodic reports.

Before being installed in the Montessori Lyceum in Zeist, the components of the SchoolVent system were thoroughly tested and validated in the TNO laboratory. This validation process ensured that the project was based on solid scientific research and ready for real-world implementation. The result is a balanced ventilation system that used heat recovery and indirect adiabatic cooling to control indoor temperature and a high-efficiency and low-pressure drop electrostatic filtration system that conditioned all five classrooms simultaneously.

Challenge:

Filtering and Cooling the Air in Classrooms

It is common for schools to suffer from inadequate ventilation in winter and too high temperatures in summer. It requires high-efficiency filtering, which traditionally leads to high-pressure drops and installation noise. Now consider a school located less than 50 meters from a busy highway. “Current ventilation systems often require expensive commissioning measurements and lack monitoring facilities during the use phase. With the development of the SchoolVent project, we have solved these problems energy-efficiently,” states Piet Jacobs, Senior Researcher from TNO.

One of the most important solutions implemented was installing a high-efficiency air filtration system (from VFA Solutions). This system was designed to remove pollutants, aerosols, and allergens from the air, improving indoor air quality for the students and staff.

The SchoolVent project uses a high-efficiency and low-pressure drop electrostatic filtration system that is scaled up to handle an airflow of 10,000 m³/hour. “This system is designed to filter out fine particulate matter (PM) effectively and other pollutants commonly found in schools located near busy roads, city center zones, or industrial areas,” guarantees Eliane Khoury from VFA Solutions. The system achieves this by using electrostatic precipitation and filtration, a process in which particles are initially charged by a controlled electric field and attracted to it, and collected on an electrically charged surface followed by a static collector.

“This type of filtration system has several advantages over traditional mechanical filters, such as a lower pressure drop and longer filter life, which results in lower maintenance costs.“

Eliane Khoury from VFA Solutions

“One of the key challenges in implementing this type of filtration system is ensuring that it can effectively filter PM while maintaining a low-pressure drop. This is important because a high-pressure drop can lead to increased fan energy consumption, which in turn can offset the energy savings achieved through other aspects of the system,” says Piet Jacobs. The SchoolVent project has achieved a low-pressure drop while meeting the filtration specifications designed to remove PM and other pollutants from the air.

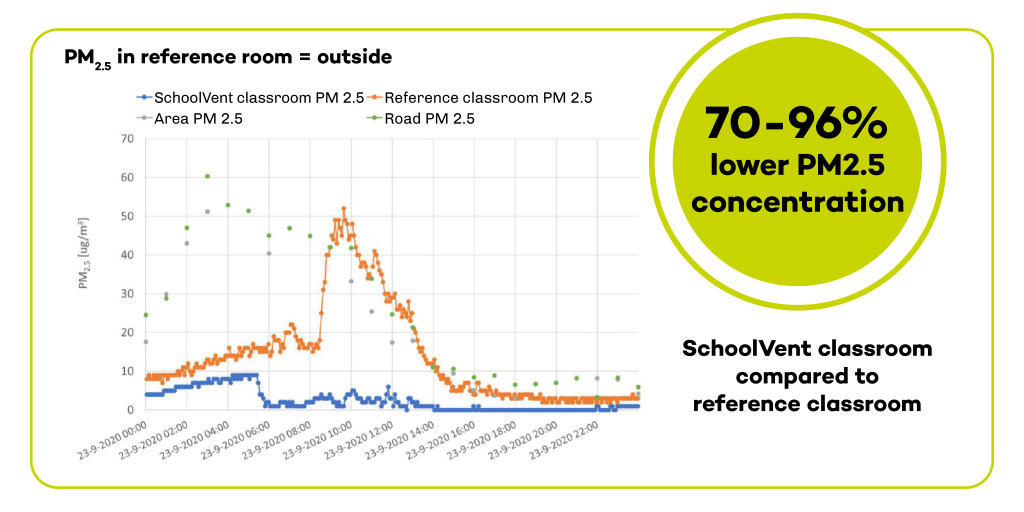

“In terms of the specific performance of the SchoolVent filtration system, monitoring during the pilot phase showed that depending on the airflow rate, the system was able to achieve a 70-96% reduction in PM2.5 concentration compared to a reference classroom. This demonstrates the system’s effectiveness in filtering out fine particulate matter, which is a significant health concern for people exposed to high levels of air pollution, says Marius Klerk from Lucam.

“In terms of the specific performance of the SchoolVent filtration system, monitoring during the pilot phase showed that depending on the airflow rate, the system was able to achieve a 70-96% reduction in PM2.5 concentration compared to a reference classroom. This demonstrates the system’s effectiveness in filtering out fine particulate matter, which is a significant health concern for people exposed to high levels of air pollution, says Marius Klerk from Lucam.

The SchoolVent system also addresses the issue of overheating in schools, especially after improving insulation, by combining heat recovery and indirect adiabatic cooling. “Heat exchanger allows heat recovery from the exhaust air and reuses it to preheat the incoming fresh air. This improves the system’s energy efficiency by reducing the energy required to heat the incoming air. The heat exchanger used for heat recovery is also used for indirect adiabatic cooling. This type of cooling works by passing the exhaust air over a wetted surface, which evaporates the water and cools the air. This cooling method is highly energy-efficient because it utilizes the coolness of the evaporating water rather than mechanical refrigeration,” explains Piet Jacobs.

In the winter, the system achieved a heat recovery efficiency between 60-75% during the pilot phase and maintained comfortable indoor temperatures, which is a significant improvement over traditional ventilation systems. Furthermore, the monitoring during the pilot phase showed that the system could maintain comfortable indoor temperatures, even during the summer when outdoor temperatures were high.

“Regarding the indoor climate, the project accomplished the requirements and obtained the class A rating for indoor climate from the Dutch Fresh Schools program (originally called PvE Frisse Scholen),” highlights Piet.

Monitoring:

The Key to Success

Lucam has developed the SMART monitoring system in which the OJ Electronic controls are integrated. OJ Air Controls are designed to optimize the performance of air handling units. These controls allow for precise monitoring and control of the SchoolVent project, ensuring optimal air quality and temperature.

Lucam has developed the SMART monitoring system in which the OJ Electronic controls are integrated. OJ Air Controls are designed to optimize the performance of air handling units. These controls allow for precise monitoring and control of the SchoolVent project, ensuring optimal air quality and temperature.

“OJ Electronics’ controls played a crucial role in the project’s success by managing the temperature and CO2 levels, the ventilation rate, and the operation of the heat recovery and cooling units. The controller also provides detailed system monitoring, allowing the team to optimize the system’s performance throughout the pilot phase. It made commissioning measurements and monitoring during the use phase more efficient, reducing associated costs. They were essential in guiding the project with useful data”, says Piet.

Lucam has implemented the OJ GreenZone® system into the project. The OJ GreenZone® is an innovative building and facility management solution designed to optimize energy efficiency, environmental control, and overall sustainability. It uses advanced sensors, automation, and data analytics to provide real-time monitoring and control of heating, ventilation, and air conditioning (HVAC) systems.

In the SchoolVent project, the OJ GreenZone® system played a key role in addressing the cooling and filtration issues. The system’s sensors monitored the facility’s temperature, humidity, and air quality in real-time, and the data were analyzed to identify areas where improvements could be made. The OJ OJ GreenZone® system also provided real-time control of the HVAC system, allowing adjustments to be made quickly and efficiently in response to environmental changes.

“The use of the OJ GreenZone® system helped to improve the cooling efficiency of the school and reduce energy consumption. It also helped improve the air quality, as the real-time monitoring and control of the ventilation system allowed for quick and efficient adjustments to address any air quality issues.“

Sebastian Wezenberg from Lucam

The benefits of OJ Air Controls are not restricted to this specific project in the school, but they can be used in any HVAC project, providing energy savings and improved indoor comfort.

“The SchoolVent project was a success and has been further optimized. In 2021, another 14 classrooms were equipped with the system,” celebrates Marius. This collaboration between Lucam and OJ Electronics exemplifies how integrating advanced HVAC technologies and efficient controls can provide cost-effective, energy-efficient, and fresh air solutions for the built environment.

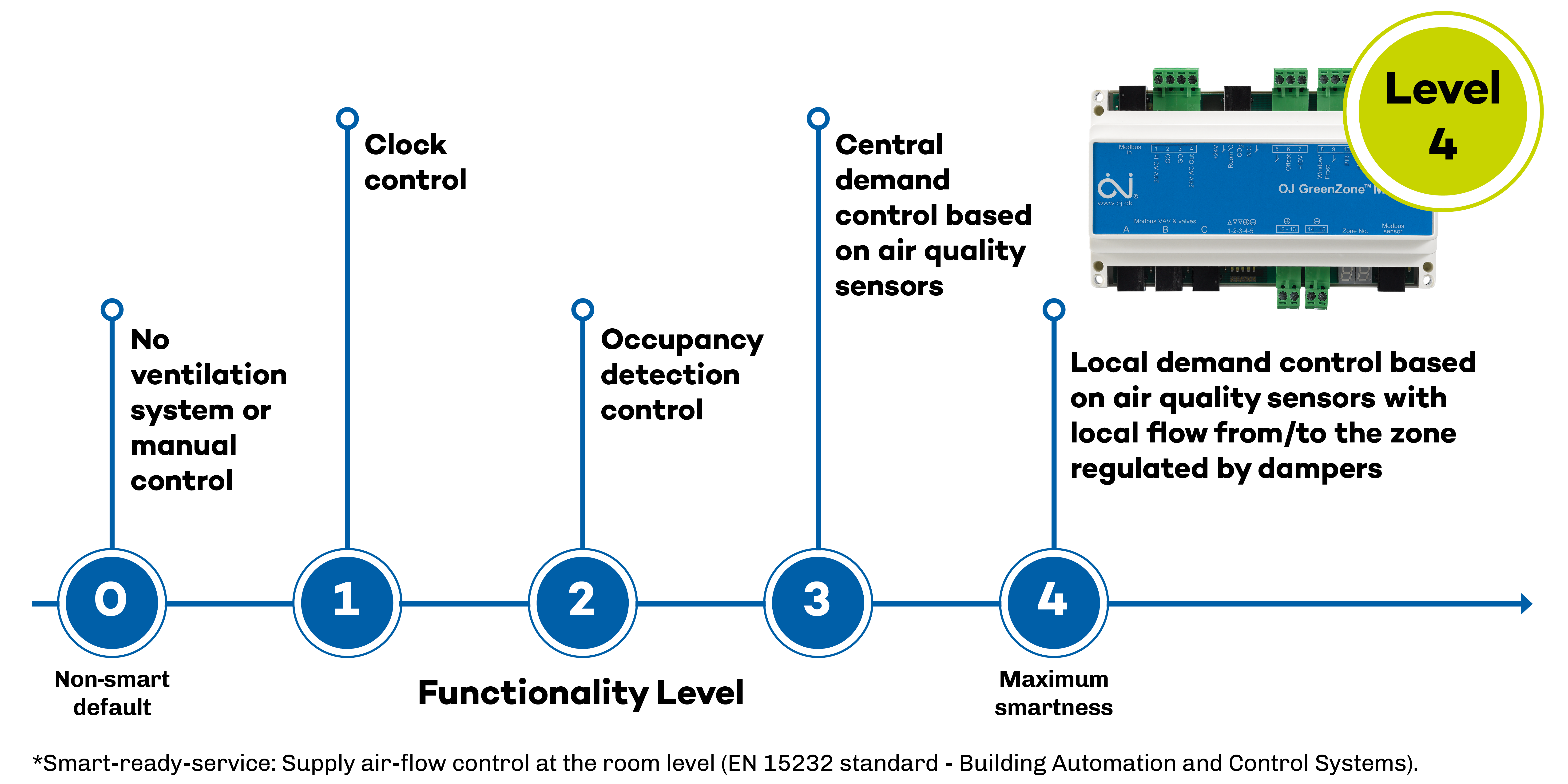

OJ GreenZone® Scored at Level 4 in the European Commission Smart Readiness Indicator (SRI) – Air Flow Control Service Group*