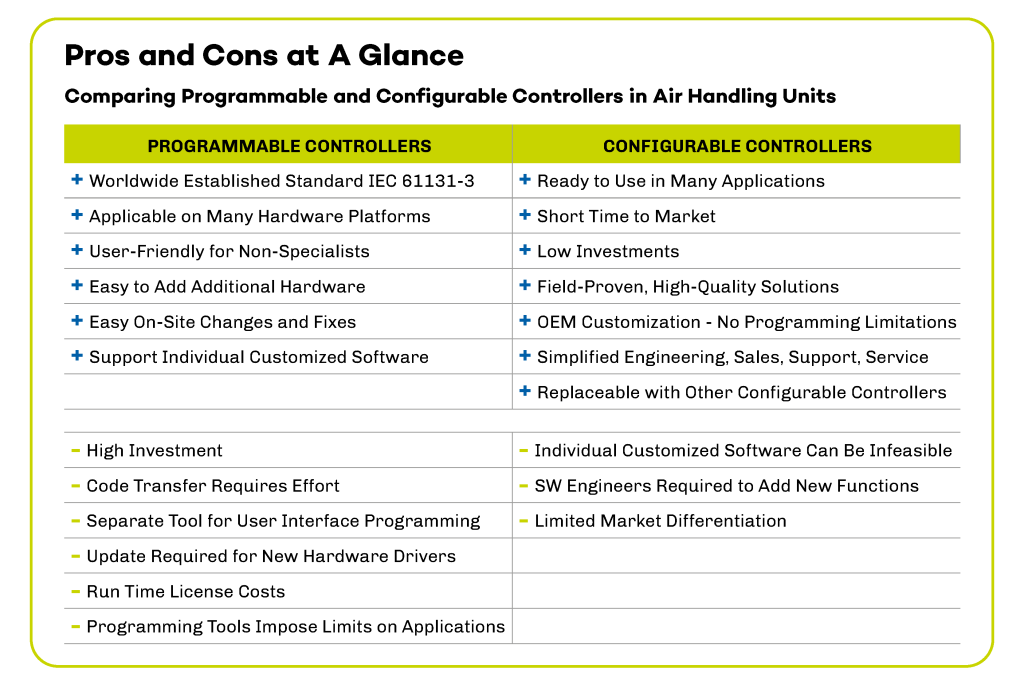

The choice between programmable and configurable controllers can play a crucial role in determining the cost-efficiency, flexibility, adaptability, and competitive advantages of AHUs. Both options come with their distinct advantages and certain challenges. This article aims to provide a comprehensive comparison of the pros and cons of programmable controllers and configurable (parametric) controllers, focusing on applications in air handling units within the HVAC industry.

Programmable Controllers

IEC 61131-3 programmable controllers have become a cornerstone in the field of industrial automation, offering a standardized approach to control system development. These controllers bring several advantages, making them widely adopted, but can also have their drawbacks. Below we explore their pros and cons.

IEC 61131-3 programmable controllers have become a cornerstone in the field of industrial automation, offering a standardized approach to control system development. These controllers bring several advantages, making them widely adopted, but can also have their drawbacks. Below we explore their pros and cons.

Advantages of Programmable Controllers

1. Worldwide Established Standard

IEC 61131-3 is an internationally recognized standard. Its universal applicability ensures consistency and interoperability across different industries and regions.

2. Applicable on Many Hardware Platforms

The IEC standard’s flexibility allows it to be implemented on various hardware platforms, providing users with a wide range of options to choose from.

3. User-Friendly for Non-Specialists

IEC 61131-3 controllers are designed to be user-friendly, enabling individuals without extensive computer science backgrounds to develop and maintain control systems. Many professionals within the AHU business will be perfectly familiar with the coding language beforehand; for example, electricians learn it at school.

4. Easy to Add Additional Hardware

Programmable controllers use software function blocks that simplify the integration of additional hardware, promoting modularity and scalability in control system design. Quite simply, it is easy to add more elements to the system.

5. Easy On-Site Changes and Fixes

IEC 61131-3 controllers facilitate quick and easy on-site modifications, making it convenient for operators to implement small changes and fixes without significant disruptions. To put it in popular terms, you can make changes even while the conveyor belt is running.

6. Support Individual Customized Software

Programmable controllers enable the development of individualized and customized software for each controller, catering to the unique demands of diverse industrial applications. It is very easy to adapt for customers: essentially, you can get the function you need right now – and if you want something else 14 days later, that will be perfectly possible too. Making tweaks along the way is simple and straightforward.

Disadvantages of Programmable Controllers

Despite their many advantages, programmable controllers may not be the right choice for your AHUs – not least due to considerations of complexity and cost. Here are some of the cons:

1. High Investment

Developing software can take a lot of time, so building an AHU control system using software function blocks can entail a substantial initial investment, limiting its feasibility in cost-sensitive projects.

2. Code Transfer Requires Effort

While it is possible to transfer code from one hardware platform to another, the process is demanding in terms of time and resources. Moving software is usually more difficult than most people think; the process ideally requires both platforms to have the same libraries, and they rarely do.

3. Separate Tool Required for User Interface Programming

Programming user interfaces is a demanding process and will often require a separate tool, adding complexity (and cost) to the development process and potentially requiring additional training for users.

4. Update Required for New Hardware Drivers

Introducing new hardware components may necessitate updates to the programming tool, leading to potential compatibility issues and increased maintenance efforts.

5. Run Time License Costs

Run-time license costs can adversely affect the overall cost-effectiveness of the control system. These costs should be regarded as part of the price of the controller.

6. Programming Tools Impose Limits on Applications

The boundaries set by the programming tools may limit certain applications, potentially restricting the flexibility of the control system in addressing complex or unique scenarios.

Summing up the pros and cons of programmable controllers, Jens Antonsen says: IEC 61131-3 programmable controllers obviously offer a standardized and versatile approach to industrial automation. Their widespread adoption owes much to their user-friendly nature and international recognition, but you should still consider the potential drawbacks such as the high initial investments and limitations in certain applications.

“Within the AHU field, some manufacturers – especially those with their own software departments – prefer to use programmable controllers because having your own software obviously means that you are in full control. Also, proprietary software can be a competitive advantage – it won’t find its way to the competitors. Still, we often find that in real life, it’s easy to end up with a ragtag collection of solutions. And that’s when you start looking for ways to reduce complexity – which configurable controllers often offer.”

Jens Antonsen, Product Manager, OJ Electronics

Configurable (Parametric) Controllers

Configurable (also known as parametric) controllers have become increasingly prevalent in the HVAC industry for good reasons: they offer a flexible and cost-effective solution to controlling air handling units. Below we delve into the advantages and drawbacks of configurable controllers, shedding light on their usefulness in the HVAC market.

Advantages of Configurable Controllers

1. Ready to Use in Many Applications

Configurable controllers cater to a vast array of AHU applications and are ready to use, providing a quick and efficient solution for various HVAC requirements. In fact, 80 to 90% of all functionalities are usually covered by the configurable controllers already available

2. Short Time to Market

One of the key advantages of configurable controllers is their short time to market. They enable developers and manufacturers to respond promptly to new market demands and changes. And the new elements are added to tried and tested, field-proven solutions so you are quicky up and running.

3. Low Investments

Configurable controllers require lower initial investments compared to developing your own software, making them an attractive choice for cost-conscious projects without compromising on functionality.

4. Field-Proven, High Quality Solutions

Configurable controllers are generally a high-quality choice: they are field-proven, ensuring reliability and performance in real-world HVAC scenarios. Developing software from scratch always involves a risk of bugs and teething problems, and such things tend to have been ironed out in the configurable versions.

5. OEM Customization Without Programming Limitations

OEM controller manufacturers can customize configurable controllers without being limited by programming tools, enabling their clients to differentiate themselves with solutions developed especially for specific brand and customer needs.

6. Simplified Engineering, Sales, Support, and Service

Having the same software underpin all your AHUs reduces complexity in numerous areas, including engineering, sales, and – not least – support and service. Such streamlining enhances overall operational efficiency in many ways; for example, all systems can be upgraded to the latest version with ease.

7. Interchangeable with Other Configurable Controllers

Configurable controllers can be replaced by another without significant complications, giving you flexibility and adaptability in case of hardware upgrades or changes in the market landscape.

Disadvantages of Configurable Controllers

1. Individual Customized Software Can Be Infeasible

While configurable controllers offer flexibility, creating individualized and customized software for individual scenarios may not be feasible. Quite simply, adjusting them to individual building projects would be too expensive. This limits their usefulness in certain applications that require highly specialized programming.

2. Software Engineers Required to Add New Functions

With configurable controllers, adding new functions often requires the expertise of software engineers. It cannot be done by electricians, for example, which means that your controls supplier needs to use specialists for system modifications or enhancements.

3. Limited Market Differentiation

Controllers are an important part of what sets a given company apart from others in the eyes of users – and configurable controllers are often standard solutions, which means that they obviously do not support differentiation: your web interface may well be the best in the world, but if a competitor also uses it, this argument loses impact.

Looking at the pros and cons of configurable controllers, Jens Antonsen says: They are a very attractive solution for the HVAC industry, offering an excellent balance between flexibility, affordability, and time-to-market efficiency. Their ability to streamline processes, especially in support and service, makes them a preferred choice for many applications. As does the fact that they let you create OEM versions of configurable controllers without being limited by programming tools. However, manufacturers and system integrators will also need to consider the specific requirements of their projects – do they need features that require customized software? – as well as the competitive landscape in the HVAC market – do we need to stand out more?

The Bottom Line

Having outlined the pros and cons of the two solutions, Jens Antonsen sums up the situation as follows: Approximately 90% of all AHUs will be perfectly happy with a configurable solution. They are more affordable and cover the vast majority of the functionalities required. What is more, the range of functionalities available in configurable controllers is market-driven: new functions are added and incorporated by popular demand, so you can still keep up with developments – or even stay ahead of the curve; for example, OJ Electronics incorporated cloud capabilities in configurable controllers before the market required it. We also offer differentiated OEM controllers, which is made feasible by the adaptability of configurable controllers.

Having said that, many companies can also benefit from choosing programmable controllers – especially larger companies who want their own software in order to stand out and have the know-how in-house. However, this can put quite a drain on service and support departments – and smaller businesses may find that they haven’t got the time nor the money to spend plenty of man-hours on developing their own software.