Everyone in the business knows that modern technology has made harmonic distortion a growing issue.

We also know the problems it can cause:

- Overheated cables, fuses, and breakers

- Nuisance trips

- Reduced system efficiency and lifetime

- Disrupted operation of sensitive electronic equipment

The issue can be tackled in various ways: through central compensation (adding a filter at the point of common coupling), by over-dimensioning the electrical supply installation, or through decentral compensation where harmonics are mitigated locally at the source. The latter method has many advantages, and so we set out to create the best possible solution. Hence, OJ Electronics now offers a series of ultra-low harmonic drives with a built-in active frontend that compensates for individual drive loads. Here we delve into some of the technical aspects of these drives, including some of the choices made in their development, the problems they resolve, and the benefits they bring for manufacturers, systems developers and end-users.

Creating the Optimum Decentral Compensation

When the OJ Electronics team first embarked on bringing our customers decentralized compensation for harmonics, we carefully examined various typologies. This was done in collaboration with external partners and university specialists to ensure that all aspects were explored, and our objective was clear: to strike the ideal balance between efficiency and cost.

“After a great deal of study and deliberation, we decided on a solution based on a Vienna rectifier. This has many benefits: you get the lowest possible number of external components, minimizing demands in terms of space and money. So on the plus side, you have compactness and lower costs due to savings in the clients’ system.”

Preben D. Jessen, Head of Drive Products, OJ Electronics

Solving the Drawbacks of Vienna Rectifers

However, all things have their limitations and drawbacks, and the Vienna rectifier is no exception. It is a unidirectional converter, which means that there will be transitions between discontinuous and continuous conducting modes. This (and other nonlinearities) is more dominant at low power levels, which makes it difficult for PI controllers with simple feed-forward to track the reference and keep the current’s total harmonics distortion (THDi) levels low.

A standard PID regulation based on a feedback signal cannot mitigate the issue. So to resolve the matter, OJ Electronics created a special algorithm. We developed a feed-forward control algorithm based on a prediction technique which works very well. Essentially, it keeps learning from the error signals received, amending the feed-forward signal. Cycle after cycle, the error decreases to near zero. The result of this ingenious solution is that you can now combine the cost advantages of the Vienna rectifier with hitherto unseen efficiency in mitigating harmonic distortion.

What Causes Harmonic Distortion?

But what causes harmonic distortion in the first place? One of the key culprits is variable speed drives. They have many advantages for businesses, optimizing energy consumption by regulating the speed of electrical motors based on current application requirements. However, they too have a drawback: they can lead to power line harmonics.

Unchecked harmonics pose various risks, including damage to sensitive electronic equipment, interference in communication devices, and inaccurate readings. They can trigger circuit breakers, blow fuses, and lead to capacitor failures. The consequences also extend to overheating of transformers, cables, motors, generators, and capacitors, resulting in energy waste and reduced equipment lifespan.

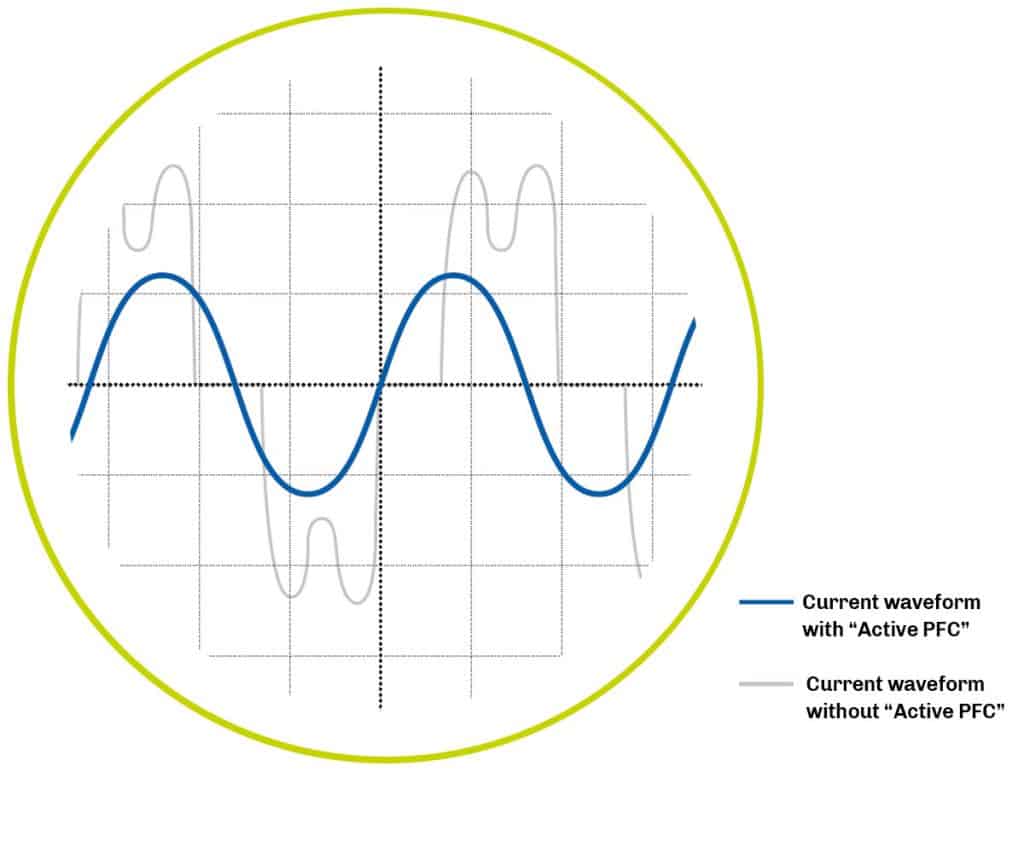

Harmonics originate from non-linear loads that disrupt the ideal sinusoidal wave form of alternating current (AC) power (Blue curve). This distortion, caused mainly by non-linear loads from variable speed drives as well as EC motors, LED lighting, computers, and much more, leads to a deviation from the pure sine wave (Grey curve). Notably, linear loads such as Direct on-line (DoL) motors do not generate harmonics but may cause phase angle displacement issues.

Harmonics originate from non-linear loads that disrupt the ideal sinusoidal wave form of alternating current (AC) power (Blue curve). This distortion, caused mainly by non-linear loads from variable speed drives as well as EC motors, LED lighting, computers, and much more, leads to a deviation from the pure sine wave (Grey curve). Notably, linear loads such as Direct on-line (DoL) motors do not generate harmonics but may cause phase angle displacement issues.

Total harmonic distortion (THD), measured as a percentage, quantifies the impact of harmonics on the network. THD is the ratio of RMS harmonic content to the RMS value of the fundamental frequency. As harmonics increase, THD rises, impacting the network.

The OJ-DV ULH drive resolves this issue with its 3-phase active frontend, typically reducing the total THDi to less than 3% while upholding a power factor greater than 0.99. Compared to our standard DV drives with up to 35% THDi, the losses can be reduced by up to 10% by using a ULH DV drive.

Advantages of ULH Drives Compared to Central Compensation

As was mentioned above, central compensation is one way of coping with higher harmonics. Choosing decentralised compensation instead has several obvious advantages: you do not need a central harmonic filter, nor to carry out calculations for it. You save space and costs – including costs for on-site installation. In one telling example, a customer avoided EUR 8,000 in costs for an external active filter.

Advantages of ULH Drives Compared to Over-Dimensioning

Oversizing the electrical supply installation is another way of coping with higher harmonics. However, this solution is expensive – and often it is not very effective, either. By using decentralised compensation instead, you no longer need to oversize the electrical equipment, making the task much simpler – and cheaper. In one example, a customer saved EUR 2,000 on the transformer, EUR 800 on the cables, fuses and breakers, and EUR 200 on installation manhours. And, of course, the customer got complete fan units that comply with the strictest standards on harmonics and technical connection requirements. Other clients will find similar effects throughout their facility, reducing costs for cables, distribution transformers, generators, switchgear and circuit breakers. Depending on equipment type, these savings can be between 10–50%.

Why ULH Drives Make Sense for You

The decision to add ULH drives to the OJ Electronics range was made for good reasons. Addressing harmonics in this way has many benefits: With ULH drives, you can use standard solutions, continuing your production without interruptions. You can easily deliver fans with ULH capabilities simply by replacing the drive you usually use with a DV ULH version – and those units can be fully assembled and tested on your factory production line just like standard fan units.

A simple way to extend your product offering while maintaining the same assembly process.

- You do not need over-sized systems – there is no need to dimension and install additional external filters and cables.

- Your installations can be simpler, smaller, and easier to plan as you benefit from simpler dimensioning of electrical equipment (cables, fuses, switches and transformers) in the system.

- You also get great reliability – a key aspect for reducing and eliminating downtime, which can be extremely costly. Your system lasts longer, and you save on capital costs and power costs.

So while the ULH drive is in itself slightly more expensive than a comparable standard drive with no harmonics mitigation, it more than pays for itself elsewhere in the system. The technical aspects are complicated, but the solution is simple. If you want to hear more about this subject, do not hesitate to get in touch.